DESIGN PROGRAM & TOOLS

MATERIAL SELECTION GUIDE

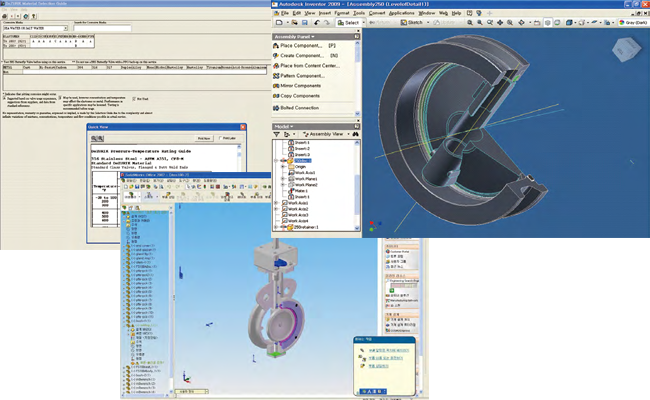

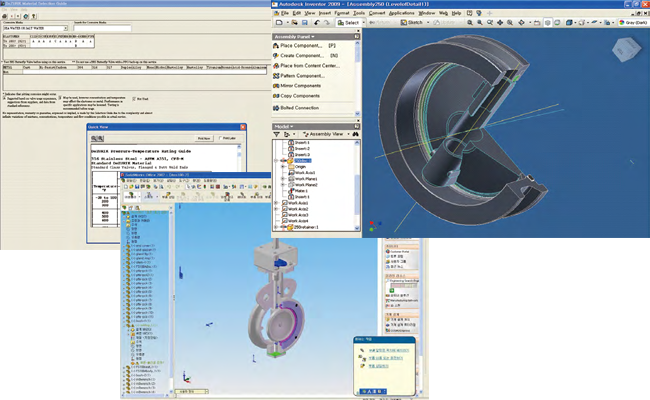

INVENTOR 2009-3D DESIGN

SOLID WORKS

MATERIAL SELECTION GUIDE

INVENTOR 2009-3D DESIGN

SOLID WORKS

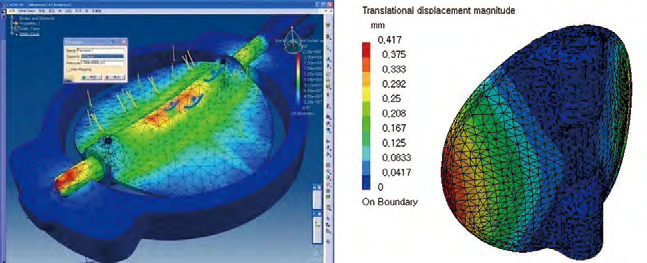

We can analyze the geometric structure of all part of valve by 3D design program tools (Inventor 2009, Solid works 2006). We can also estimate dynamic stains of material under the condition such as high pressure, high temperature and high torque before making products.

Since the stem and disc are located on center position on the rubber seat, the principle of seeing mechanism is using the force of resilience of rubber. A perfect zero leakage seal at bi-direction is obtained by the compression of the seat between the valve body and the edge of the disc.

Since the stem is eccentric from the seat ring, the disc is in contact with the soft only when the valve is completely closed. The benefits from the double eccentric disc design.

Longer Service life due to hard to wear seat ring. When in the closed position, the seat ring ensures complete sealing. Less seating torque Easy replacement of the seat ring without removing the stem due to offset stem design.